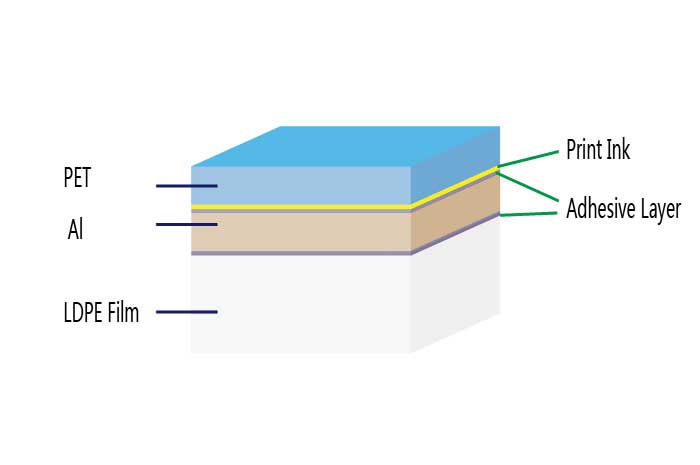

PET/AL/LDPE foil laminate proves to be one of the most reliable foil structures in the flexible packaging industry, offering durability, high performance, and cost-effectiveness for various food and daily products. The craftsmanship and quality control processes are being refined in our manufacturing plant to ensure this foil is produced with superior reliability against customers’ requirements.

PET film exhibits excellent printability, mechanical properties, processing stability, high-temperature resistance, and grease resistance, making it an ideal print film in the flexible packaging field. Aluminum foil is of the best barriper properties among all the substrate film materials. When these 3 layers are combined into finish foil laminate, it will be enabled with superior quality to provide best protection and preserve for the products.

The BRCGS Global Standard Food Safety has set the benchmark for over 25 years. Adopted by over 22,000 sites in more than 130 countries, the standard is accepted by leading global brands and retailers.

We hereby commit our foil laminate will be in compliance with FDA regulations, and thir-party inspection is available on customer’s request.

Metallized paper is playing a more and more important role in compostable packages. As paper is considered the biodegradable materials which can degrade under so many nature conditions, so the compostable packages acheived with metallized paper are much flavored in the consumer market.

The PET film we adapt are in compliance with EC and DFA regulations performed by SGS entity.

This certificated is carried by NSF International against FDA 21 CFR 178.3910 and ASTM F963-11

LDPE film is inspected by china institute to comply with food safety regulations.

The printing inks used are certificated to comply with directive 2011/65/EU (RoHS).

The adhesives we use are certificated to comply with directive 2011/65/EU (RoHS).

Rotogravure printing produces high-quality images with excellent printing precision, high output speed at very effective costs.

Flexographic printing is a modern version of letterpress printing and can be used on most materials.

Digital printing offers flexible options for small-volume jobs and sample produce at lowest cost, without the making of print cylinders.

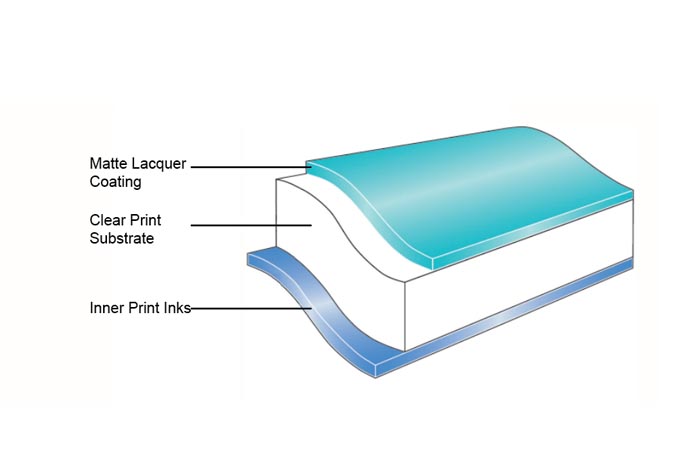

A layer of matte lacquer is coated on the exterior of the package to eliminate the glossy reflection on the appearance of a normal package. This is intended to create a high-quality visual effect for consumers, which may lead them to a higher buying rate. Additionally, some parts can be left glossy, which proves an effective method of guiding consumers to read the intended information.

Now, matte lacquer are widely used on the packages for numerous products, ranging from foods to cosmetics, pet foods, and household products.

Dry lamination process combines two layers of substrate films together under the function of solvents.

Solvent-free lamination is able to achieve higher operation speed, lower cost, and less environmental impact.

Extrusion coating achives the combination of different layers by molten polymer, which can operate large orders at much lower cost.

The foils are supplied in rolls, to run on the fill-form-seal lines at customer’s sites.

Flat pouches are convenient and cost-effective for low-capacity products, like spices and condiments.

Premade pillow pouches are supplied to customer when he does not have a filling line.

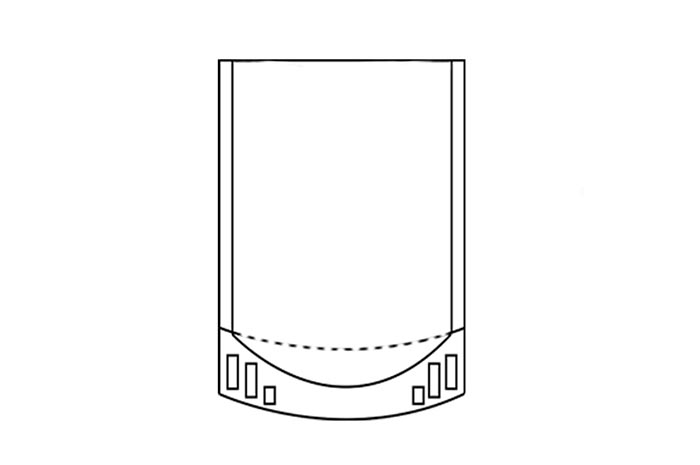

Standup doypack is intended for a great self-standing profile and branding.

The side folded pouch is able to hold more products with the same dimensions.

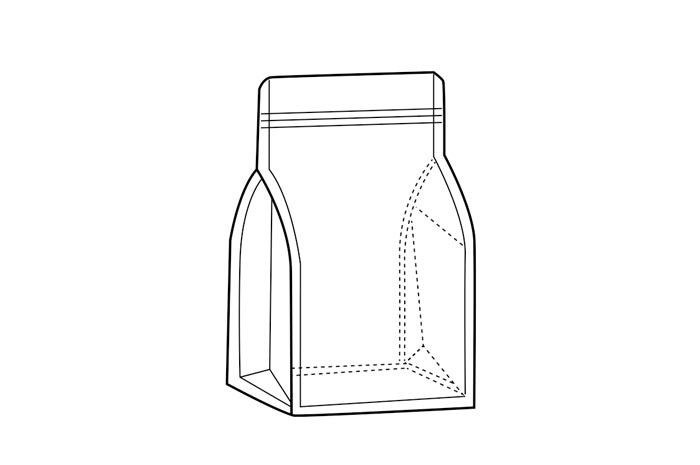

Quad seal pouch is able to create sharp body effect for the final filled package.

More sturdy and re-sealable, block bottom pouches are widely popular for numerous products.

Bag-in-box pouches are more flexible and cost-effective options for liquid products.

A re-sealable zipper is able to preserve the products for a longer time after the pouch is opened.

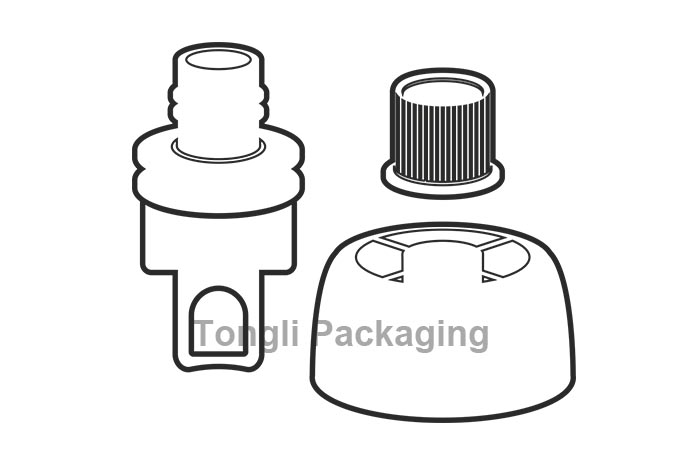

Better use experience is provided to the consumers by the spout & closure system.

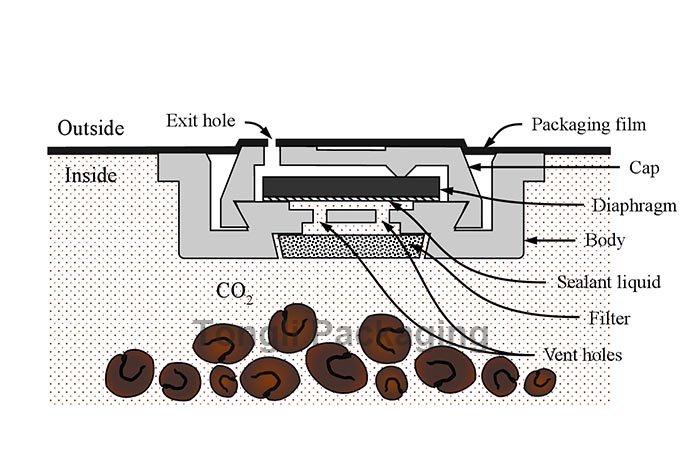

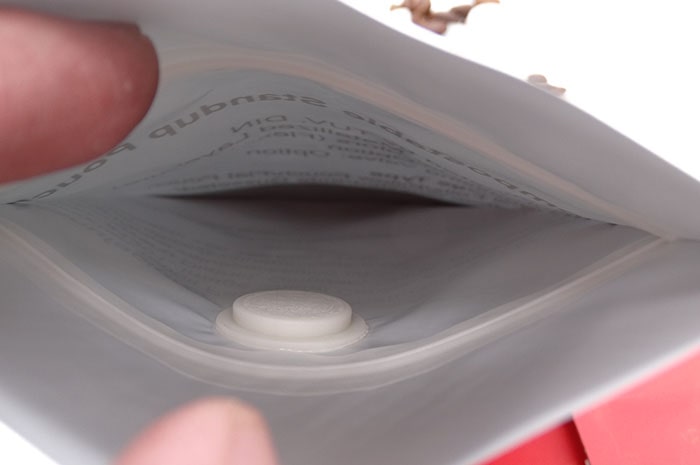

Degassing valve works as an effective measure for modified air packaging.

Plastic handles provide convenience for the consumers when the package is heavy duty.

This carabiner hook provides flexibility and creativity for some products.

Horizontal filling machines are designed to provide fast, precise, durable packaging solutions for numerous products, like biscuits, bakery products etc

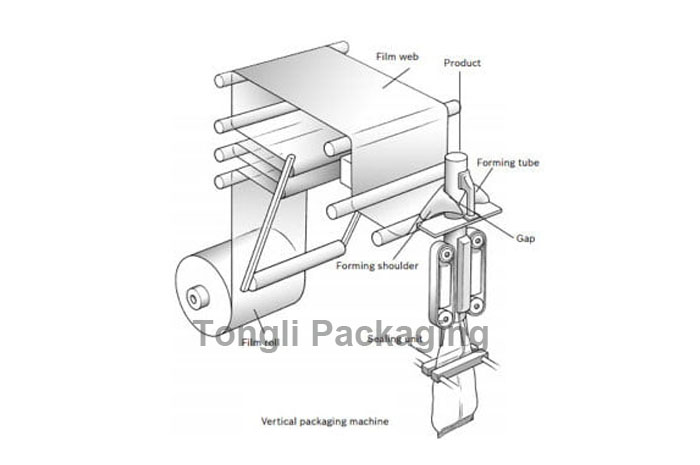

Our foils can run well on most of the vertical filling machinery with easy form, fine sealing, and perfect appearance.

The premade pouches are running at the gallop of the machine speed to maximize the production effeciency.

Spout pouches are well accepted by numerous products, and can be filled on the filling machineries at high speed.

Manual filling and sealing proves to be the lowest cost for any startup business.

Drop testing should be considered a very reliable way to check if the strength of PET/AL/LDPE foil pouch is sufficient to protect the products, as it simulates the way products fall off grocery shelves and the finished bag will undergo a sudden shock.

In our daily quality control (QC) work, we perform drop tests on each order. Of course, the standard for this drop test should be decided based on customer needs.

Anti-pressure test is conducted on our test equipment, which applies a certain pressure and period on the air-flushed bags, and see if they burst. It is able to provide exact data on the ultimate strength of the foil materials, and helps us to determine the exact materials and thickness against the requirement of the customer’s products.

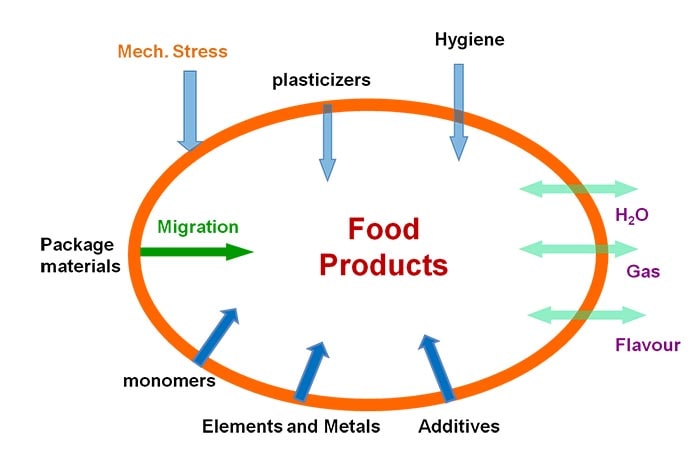

This migration test is conducted on the foil materials that is brought into direct-contact with foods. As there are adhesives in the foil, plasticizer, additives and produce aids in the film materials that may bring hazards to human safety, this test is to have an assessment over the foils, and ensure it does not pose a risk to health.

This test can not be finished in our plant, and will have to be entrusted to third-party inspection entity, which is able to provide a sufficient evaluation against the specific regulations of EC, FDA, or any other legislations.

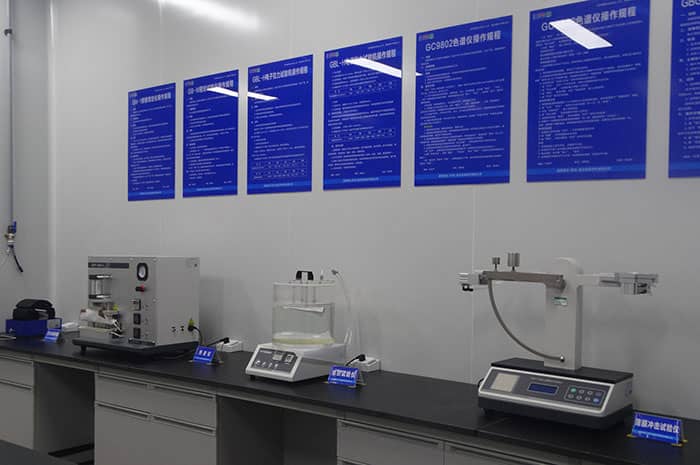

Our commitment to quality is evident in the regular laboratory tests we perform on substrate film and laminated foils. These tests provide valuable data that not only help us determine the best film materials for our customers’ requirements but also form the basis for refining our craftsmanship and QC work. This ensures we meet the stringent needs of the market, giving you confidence in our packages.

the ability of the film to slide against itself or another surface

We are glad to share our knowledge and experience regarding the application of PET/Al/LDPE foil laminate for each products, and you may read it in details and welcome to reach us whenever you have any questions. We are sure to be of the best assistance for your packaging needs.

Artwork can be printed on MDO-PE film, which is an alternative print substrate of PET film.

PVDC Coated Cellulose film is of as good printability as PET film, and the lining layer can be PBS for home compostable packages.

As environmental concerns grow, more and more companies are looking for eco-friendly and sustainable alternatives to traditional plastics. Protecting the environment requires far-reaching projects, that’s why Tongli is always looking for new ways to improve. Lucky for us, we now live in a world where it becomes easier to source sustainable materials, and now we are moving steadily to a more sustainable future.