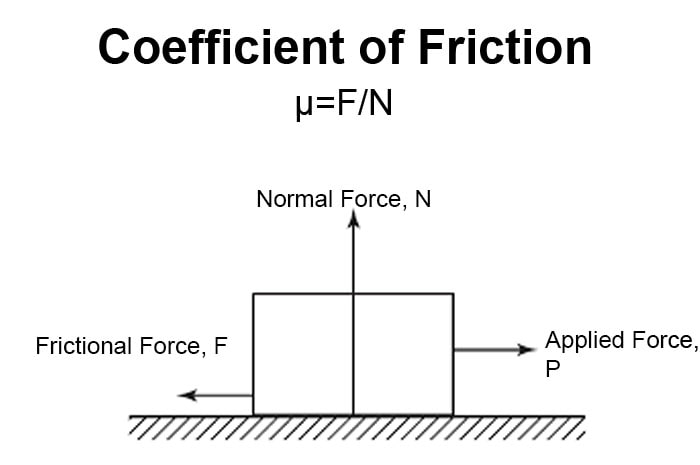

The coefficient of friction in flexible packaging greatly affects how easily one surface slides over another. This factor is crucial in packaging, as it ensures smooth movement on packaging equipment and allows for effective stacking and transportation of packaged products without slippage.

To create various package types for different products, our printed rolls typically need to operate on either horizontal-fill-form-seal (HFFS) machinery or vertical-fill-form-seal (VFFS) machinery, depending on the product flow. A higher coefficient of friction can make it more difficult for the rolls to run, which not only increases power consumption but also reduces the production rate. Conversely, if the coefficient of friction is lower than the normal range, the rolls can become too slippery, leading to unstable operation on the machinery. Generally, we maintain the kinetic coefficient of friction between 0.12 and 0.35 to accommodate most filling lines available in the market.

In this post, we are going to share the details of coefficient of friction test on triplex aluminum foil laminate PET/AL/LDPE, hope it helps you to customize your own perfect packaging.

Sample Foil Laminate

Here, we get triplex-layer aluminum foil laminate well prepared. The foil structure is PET 12um/AL 7um/LDPE 45um, with an overall thickness of 65 microns.

- PET 12 µm, means polyethylene terephthalate membrane stretched in machine direction and transverse direction with thickness 12 microns (equals to 0.48 gauge). It is of great printability, mechanical stability to work as the print substrate in the flexible packaging industry.

- Al 7 µm, stands for food-grade aluminum foil sheet with thickness 7 microns, which is the most cost-effective foil applied in the flexible packaging industry. It is non-toxic, corrosion resistant, light-weight, durable and high barrier.

- LDPE 45 µm, stands for low-density polyethylene film produced by blown process with thickness 40 mirons. It can be modified to meet the stringent requirements of various products.

These 3 layers are combined together through dry lamination and solvent-free lamination craftsmanship in our manufacturing plant.

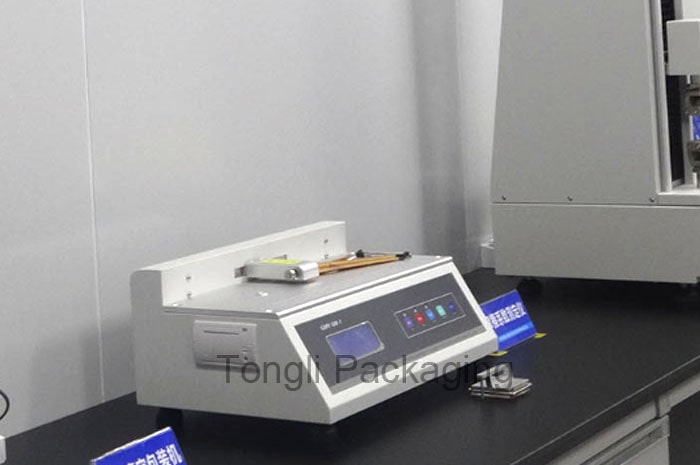

Coefficient of Friction Tester

Our laboratory is equiped with coefficient of friction tester GM-4 supplied by GBPi, a reputable manufacturer of lab instruments in china market. We perform the test on a regular basis, forming a fundamental part of our QC work.

Coefficient of Friction Test Standards

ASTM D1894 is the standard test method for static and kinetic coefficients of friction of plastic film and sheeting. It provides a procedure to measure the frictional properties of plastic materials that are often used in the flexible packaging applications. We follow ASTM D1894 to conduct the coefficient of friction test in our laboratory.

Coefficient of Friction Test Values

The values of this coefficient of friction test on Aluminum Foil Laminate (PET12/Al7/LDPE45μm) are written in the table below, for your refrence.

| Aluminum Foil Laminate (PET12/Al7/LDPE45μm) | Coefficient of Friction Values (Kinetic) | Coefficient of Friction Values (Static) |

| #1 | 0.168 | 0.188 |

| #2 | 0.165 | 0.177 |

| #3 | 0.143 | 0.147 |

| #4 | 0.143 | 0.153 |

Coefficient of Friction Test Video

We get this test process recorded by video, through which you can have a further understanding. Enjoy!

Conclusion

The coefficient of friction matter so much in the flexible packaging materials, which should be well crafted to ensure them running well on the customers’ filling lines. The laboratory tests formulate an insepratable part of our quality control work, which improve the success rate of the rolls, and more importantly eliminates the risks during manufacturing.

Of course, the coefficient of friction are not constant after the produce. It can be influence by temperature, humidity, sunlight and aging,etc. You are advised to reach our professional team for further consult to make the best use of these foil laminates.