Superior coffee packaging will not only carry a good communication between the brand and its customers, but also deliver the very best freshness of the coffee from the roast site to them. Among all the packaging film materials, aluminum foil sheet is considered to be of the best barrier property and aroma protection for coffee products. When laminated with other substrate films, multi-functions can be achieved on the same foil laminate, formulating the basis of high-quality coffee packaging.

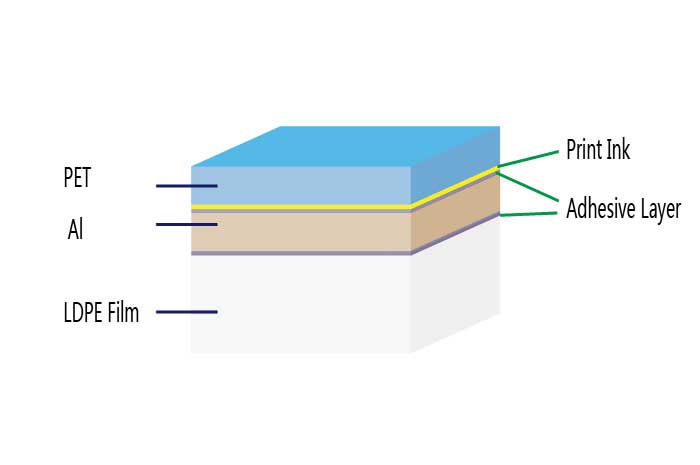

This triplex laminate PET/AL/LDPE occupies the large majority of aluminum foil coffee bags and foils, as it finds a good cost-effective solution with superior quality. It can be accepted by most of the coffee roasters and brands in the market.

From top to bottom, the diagram lists film materials from outside to inner side. So, you can understand, PET works on the outside layer, and Al works as middle support layer, with LDPE film working as the inner sealing layer. These 3 layers are combined together with adhesives, to form a finished laminate applied in coffee packaging.

In this post, we will provide a detailed analysis of this triplex laminate and explore what it can offer for your packaging needs.

Exceptional Printing Capability

PET film can be considered the most ideal print substrate among all the flexible packaging materials for nearly all the artwork designs created in the coffee packaging field.

PET film is of excellent clarity, which will not affect the presentation of any colors when it is reversely printed on the inner side on our gravure print press.

PET film is of great tensile strength and dimension stability, which will not distort under the web tension applied in the gravure printing system. This is highly favored in priting the artwork designs that may contain 8~10 colors, which requires a stable base for the accurate overlapping of different colors.

To ensure proper ink adhesion on print substrates, the surface energy of the film should be at least 38 dynes/cm. Untreated PET film typically has a surface energy ranging from 42 to 46 dynes/cm, while corona-treated film can achieve 54 dynes/cm or higher. This is significantly better than BOPP film, which may lose surface energy, dropping to around 32 to 36 dynes/cm within 3 to 4 months after production. The reduction in surface energy can happen even more quickly when the film is stored in a high-humidity environment. However, the surface energy of PET film may still remain more than 42 dynes/cm after being stored in the warehouse for more than a year. So, more and more artworks are being printed on clear PET films.

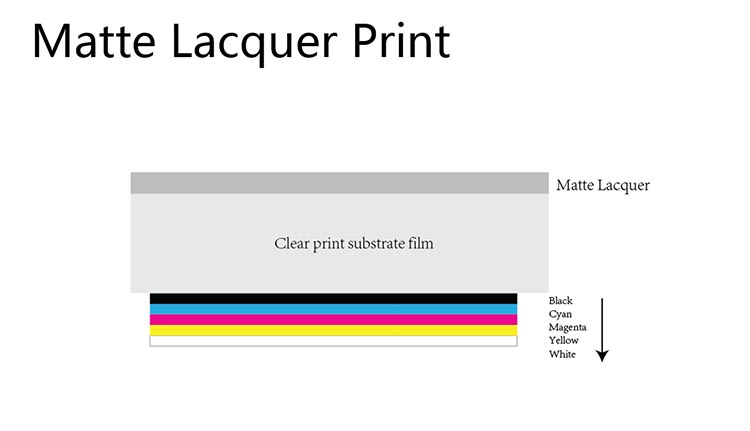

On the other hand, a large mojority of the coffee packaging artworks may require an additional matte lacquer coating on the outside of PET film, to increase the visual appealing. The matte lacquer coating is shown in the diagram below.

In our manufacturing, matte lacquer coating on PET film should be the most mature. Not to mention other effect, such as hot stamping, that can be easily applied on the outside PET film.

so, for this PET/AL/LDPE foil laminate, PET film indeed works as a very good print substrate that can present nearly all the artworks of coffee packaging.

Superior Barrier and Aroma Protection

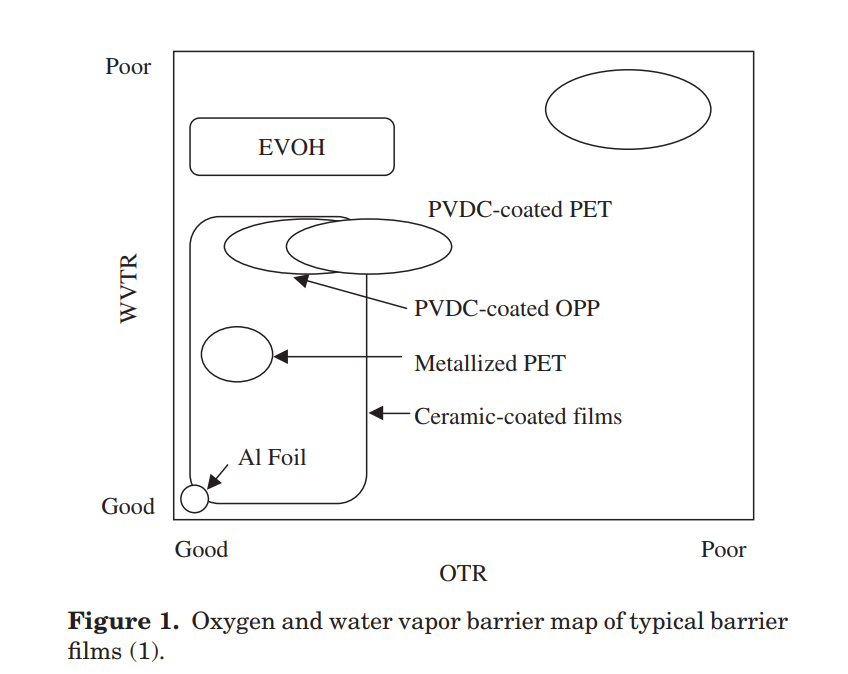

The main barrier property for this foil laminate PET/AL/LDPE is based on aluminum foil. The diagram shows the WVTR (short for water vapor transmission rate) and OTR (short for oxygen tranmission rate) of typical barrier films in the flexible packaigng industry, and it is very easy for you to figure out, the aluminum foil is extremly good at both.

To well presever the freshness and aroma of the products, the package should protect the coffee products from the outside oxygen, moisture, sunlight etc. Aluminum foil is made of aluminum with purity higher than 99.9%, and some elements are used to form an alloy. So the thin metal sheet can be an effective blocking wall against relative larger molecule such as H2O, O2.

| Material | WVTR @38℃, 90% RH cc/m2/24hr | OTR @23℃, 0% RH cc/m2/24hr |

| Aluminum Foil 7 microns | < 0.01 | < 0.01 |

Based on our experience, aluminum foil can provide the best barrier property for the finished package, and protect the aroma of coffee in a good state as long as possible.

Malleable Thickness

The overall thickness of PET/AL/LDPE foil laminate can be easily adjusted against the specific requirements for the coffee packages. The below table lists the most common thickness of PET, AL, and LDPE applied in flexible packaging industry, which forms the basis to adjust the thickness of finished foil.

| Material | PET (μm) | Aluminum Foil (μm) | LDPE (μm) |

| Thickness | 12, 23 | 7,8,9,10 | 30~200 microns |

So, the overall thickness of this finished aluminum foil laminate will range from 50 microns to a maximum 225 microns, which is able to cover the mainstream needs in the coffee packaging market.

Smooth Appearance

PET film is of high temperature resistance, which can withstand the high temperature during the heat sealing process. Usualy, the sealinig temperature ranges from 160 to 220 celsius degreee, without any damaging to the surface. So, for this foil laminate, the appearance can always be smooth, neat and clean during the form process.

Large capacity up to 5Lb

This triplex foil laminate PET/AL/LDPE can be converted to 5 Lb coffee bag with adequate properties for its purpose. In most cases, block bottom and side gusseted bags are preferred as they are more likely to present a lovely package with relatively smaller package dimensions.

Excellent Standup Portrait

With the thin layer of aluminum foil entrapped between PET and LDPE layer, this foil is achieved with enough toughness and stiffness, which will ensure a great standup portrait when coffee is filled. Additionally, the properties of LDPE film can be modified to get expected toughness for the finished foil.

The foil laminate can be converted to types of coffee packages, like bottom gusseted bag, side gusseted bag, quad seal bag and more widely used block bottom bags.

Here, you may watch the video to understand the great standing effect of our various coffee bags.

Human Food Safety

All the film materials, inks, adhesives and solvents we use to produce this foil laminate are in full compliance with Title 21 Code of Federal Regulations (CFR). In EU area, it complies with the relevant requirements of regulations 2023/2006/EC (GMP). You will be able to browse the relative certificate inspected by third-party entities on all of our film materials here.

Superior Sealing Strength

Due to the excellent seal properties of inner LDPE film, and great bonding strenght of the foil laminate, superier sealing strength can be achieved on this triplex structure PET/Al/LDPE. Usually, 50~70N/15mm can be obtained through this triplex foil laminate, which is able to achieve strong joint in the sealed place of the finished packages.

You are advised to have a further understanding on the seal strength test here.

Great Mechanical Protection

It is very important to get a strong package to provide superior protection for the inside products all the way along its business circle. A bad weak package will just break the customers’ heart to enjoy your products, and will make them never purchage again.

Luckily, PET/AL/LDPE foil laminate will be able to make a strong package not only for 12oz, but also well capacable of 5lb.

In our manufacturing plant, we perform the drop test on each order on a regular basis, to ensure each and every of the bags we produce will just make a great work.

You are advised to watch the videos showing the process of drop test on different capacities.

Drop test of 12oz block bottom coffee bag

Drop test of 1000 gr block bottom coffee bag

Drop test of 5lb block bottom coffee bag

Function Options

Based on this foil laminate, one-way degassing valve, re-sealable zipper, tin tie, or plastic handle are available to be customized on the finished packages.

Ok, here we come to the end of this post, and we have to say, this foil laminate PET/AL/LDPE is one of the very best materials for coffee, finalizing the superior packages at economical cost. You are advised to reach us for further assistance whenever you have any questions regarding coffee packaging.