In flexible packaging industry, several film materials will have to be combined together to function in a whole package. The package is expected to present excellent overall properties when these layers are tightly bonded, like one film.

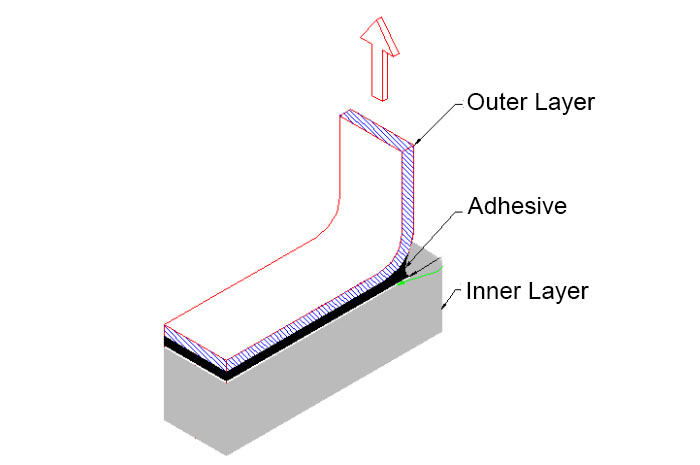

Peel strength is a crucial indicator of the adhesive bond between two film materials, showcasing the force required to detach one from the other at a designated angle. This strength is typically quantified in terms of force—measured in units such as Newtons or pounds—needed to separate a specified width of the bond line. Essentially, it gauges the resilience of the connection, revealing how well two surfaces cling to each other under the strain of separation.

In this post, we are going to analyze the details of the peel strength test on triplex foil laminate PET/AL/LDPE, hope it helps you to choose the perfect packages.

Sample Foil Materials

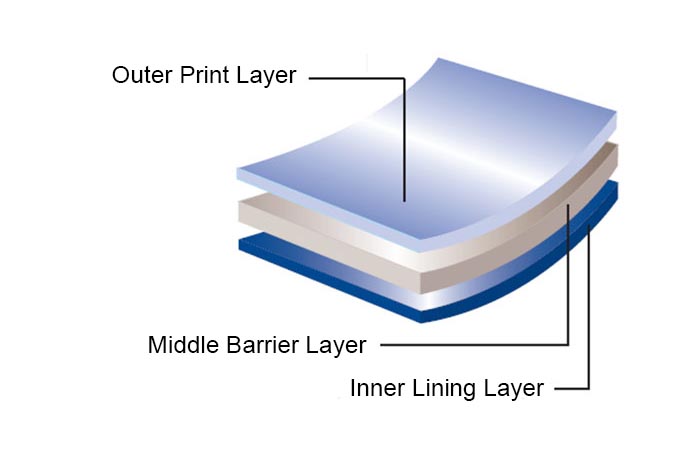

Here, we get triplex-layer aluminum foil laminate well prepared. The foil structure is PET 12um/AL 7um/LDPE 45um, with an overall thickness of 65 microns.

- PET 12 µm, means polyethylene terephthalate membrane stretched in machine direction and transverse direction with thickness 12 microns (equals to 0.48 gauge). It is of great printability, mechanical stability to work as the print substrate in the flexible packaging industry.

- Al 7 µm, stands for food-grade aluminum foil sheet with thickness 7 microns, which is the most cost-effective foil applied in the flexible packaging industry. It is non-toxic, corrosion resistant, light-weight, durable and high barrier.

- LDPE 45 µm, stands for low-density polyethylene film produced by blown process with thickness 40 mirons. It can be modified to meet the stringent requirements of various products.

These 3 layers are combined together through dry lamination and solvent-free lamination craftsmanship in our manufacturing plant.

Peel Strength Testing Equipment

Standard Test Methods

ASTM D1876 is the standard test method for peel resistance of adhesives (T-Peel test). It outlines the determination of the relative peel resistance of adhesive bonds between flexible adherends by means of a T-type specimen using a tension testing machine. We follow this standard to conduct the peel strength test in our laboratory.

Peel Strength Test Values

The values of this peel strength test are listed in the table below, for your reference.

| Foil Laminate (PET12/Al7/LDPE45μm) | Peel Strength |

| #1 | |

| #2 | |

| #3 | |

| #4 |

Peel Strength Test Video

You are advised to have a further understanding on this test process by watching the video below.

Conclusion

We are able to present the triplex foil laminate PET/AL/DLPE with excellent bonding strength for the requirements of numerious products. The laboratory tests help us to grab the exact properties of the foil laminate and refine our craftsmanship to output trustworthy packaging materials. You are advised to reach our professional team for further support whenever you have any questions regarding the packaging.