Tensile strength refers to a plastic material’s ability to endure a maximum amount of tensile stress without failing. Generally, the higher the tensile strength, the more durable the package can be. When a product falls off the good shelves, it experiences significant shock at the moment it hits the ground, which places tremendous stress on the package. So, The package should be made from film materials with excellent tensile strength to ensure a protective design.

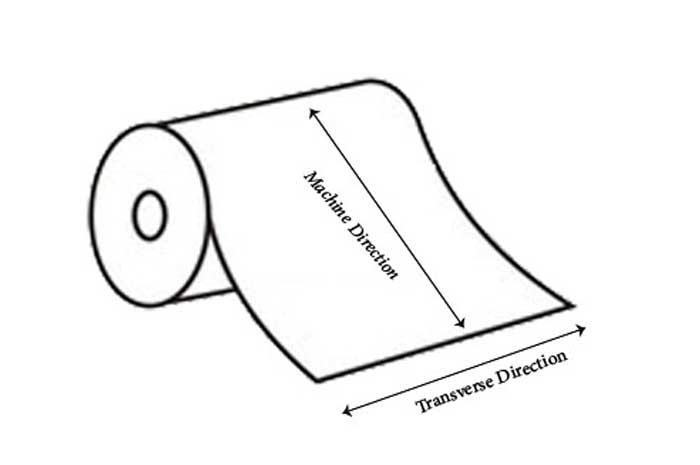

Machine Direction (MD) and Transverse Direction (TD)

When it comes to tensile strength, machine direction and transverse direction should be both evaluated. The machine direction (MD) of a film roll refers to the direction in which the film is manufactured or processed during production. It is normally done by means of a machine direction orienter (MDO) via rolls with increasing speeds The oreintation of the polymer chain will affect the tensile strength and flexibility of the film roll. While the machine direction runs along the length of the roll, the transverse direction spans the width of the film. Typically, films may exhibit different tensile strength, elasticity, and other mechanical properties in the transverse direction compared to the machine direction.

Sample Roll Foil

Here, we get triplex-layer aluminum foil laminate well prepared. The foil structure is PET 12um/AL 7um/LDPE 45um, with an overall thickness of 65 microns.

- PET 12 µm, means polyethylene terephthalate membrane stretched in machine direction and transverse direction with thickness 12 microns (equals to 0.48 gauge). It is of great printability, mechanical stability to work as the print substrate in the flexible packaging industry.

- Al 7 µm, stands for food-grade aluminum foil sheet with thickness 7 microns, which is the most cost-effective foil applied in the flexible packaging industry. It is non-toxic, corrosion resistant, light-weight, durable and high barrier.

- LDPE 45 µm, stands for low-density polyethylene film produced by blown process with thickness 40 mirons. It can be modified to meet the stringent requirements of various products.

These 3 layers are combined together through dry lamination and solvent-free lamination craftsmanship in our manufacturing plant.

Test Equipment

Our laboratory is equiped with GBH-1T tensile strength tester supplied by GBPI, which enables us to grab the invisible data of any substrate film we source, and any foil laminate produced in our plant.

Test Standards

We follow ASTM 882 to conduct the tensile strength test in the laboratory of our company. This standard applies specifically to the tensile properties of thin plastic sheeting. Testing should ideally occur at a standard temperature, commonly around 23°C (73°F). However, if the material will be used in different environments, tests may also be conducted at elevated or reduced temperatures to simulate real-world conditions.

Tensile Strength Test Values

The values of the tensile strength test are listed in the table below.

| Item | Machine Direciton (Mpa) | Transverse Direciton (Mpa) |

| PET12/Al7/LDPE45 | 80~85 | 50~55 |

Tensile Strength Test Videos

You are advised to have a further understanding on this test process by watching the videos below.

Machine Direction

Transverse Direction

Conclusion

Trpilex-layer foil laminate PET/AL/LDPE is of great tensile strenght, to meet the stringnet requirements of various products in different forms, such as tomato ketchup, coffee, mik powder, pet foods, dried fruits etc. However, the thickness of the foil materials will have to be seriously evaluated before it is put into use. Sometime, the foil laminate may have to be reinforced with an additional layer of BOPA or PET layer.