For any flexible pouch package, it is necessary to weld and seal one piece of foil laminate with another to create hermetically integrated packaging. This seal not only keeps oxygen and contaminants away from the products but also ensures that they are securely protected from the manufacturing site to the store shelves.

We perform the seal strength test and airtight property test on a regular basis to ensure a perfect seal is achieved on each flexible pouch.

Here, in this post, we are going to share the details of the seal strength test.

Sample Foil Laminate

As shown above, this is a roll laminate with customer artwork printed on the surface. The foil structure is PET 12um/AL 7um/LDPE 45um, with an overall thickness of 65 microns.

- PET 12 µm, means polyethylene terephthalate membrane stretched in machine direction and transverse direction with thickness 12 microns (equals to 0.48 gauge). It is of great printability, mechanical stability to work as the print substrate in the flexible packaging industry.

- Al 7 µm, stands for food-grade aluminum foil sheet with thickness 7 microns, which is the most cost-effective foil applied in the flexible packaging industry. It is non-toxic, corrosion resistant, light-weight, durable and high barrier.

- LDPE 45 µm, stands for low-density polyethylene film produced by blown process with thickness 40 mirons. It can be modified to meet the stringent requirements of various products.

These 3 layers are combined together through dry lamination and solvent-free lamination craftsmanship in our manufacturing plant.

Seal Strength Test Equipment

We conduct the seal strength test on this tensile tester, which can automatically record the data into the system.

Seal Strength Test Standards

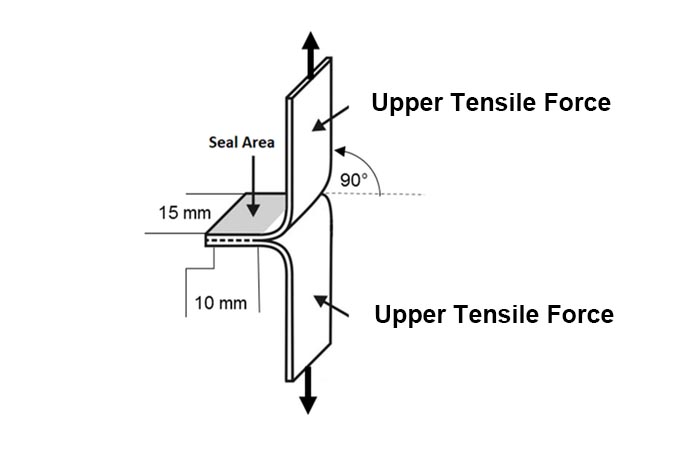

ASTM F88 outlines the standard test methods for determining the seal strength of flexible barrier materials, specifically measuring the force needed to separate a test strip containing the seal. We follow ASTM F88/ standard to conduct the seal strength test in our laboratory.

Seal Strength Test Values

The values of this seal strength test on aluminum foil laminate PET12/AL7/LDPE45μm are written in the table below.

| Aluminum Foil Laminate (PET12/Al7/LDPE45μm) | Seal Strength Test (N/15mm) |

| #1 | |

| #2 | |

| #3 | |

| #4 |

Seal Strength Test Video

We get this test process recorded by video, and you may have a further understanding on this test with the video below.

Conclusion

Aluminum foil laminate PET/Al/LDPE is able to present excellent seal strength needed to achieve a great protection for the products. Regular tests and close observations will help us to grab the actual performance of the seal in each flexible pouch, and ensure each order is produced meeting the customers’ requirments.

Of course, the seal strength can be improved by increasing the thickness of LDPE sealing layer, modification of LDPE formulas, and additional film layer such as BOPA into the foil laminate.

The customers’ needs should be seriously studies, so the best packaging materials can be decided to present great packages for the customers’ products. You may contact our professional team for further support whenever you have any questions regarding the packaging.