Anti-puncture ability, also known as puncture resistance, refers to a material’s capacity to resist penetration by a sharp object, like a nail or a piece of glass. When the film materials are intended for some products with sharp edge or point, like rice, dog chews, bone products, the anti-puncture ability should be seriously evaluated and tested, to ensure the final package to be a great protection for the products.

Sample Foil Materials

Here, we get triplex-layer aluminum foil laminate well prepared. The foil structure is PET 12um/AL 7um/LDPE 45um, with an overall thickness of 65 microns.

- PET 12 µm, means polyethylene terephthalate membrane stretched in machine direction and transverse direction with thickness 12 microns (equals to 0.48 gauge). It is of great printability, mechanical stability to work as the print substrate in the flexible packaging industry.

- Al 7 µm, stands for food-grade aluminum foil sheet with thickness 7 microns, which is the most cost-effective foil applied in the flexible packaging industry. It is non-toxic, corrosion resistant, light-weight, durable and high barrier.

- LDPE 45 µm, stands for low-density polyethylene film produced by blown process with thickness 40 mirons. It can be modified to meet the stringent requirements of various products.

These 3 layers are combined together through dry lamination and solvent-free lamination craftsmanship in our manufacturing plant.

Test Equipment

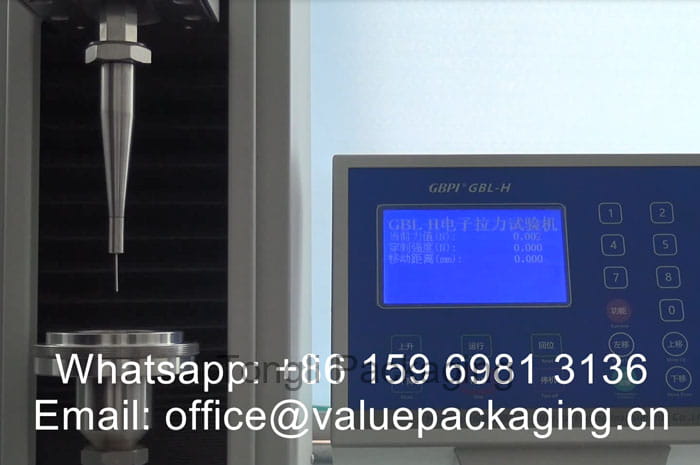

On our GBH-1T tester, we are able to perform the anti-puncture ability test on any substrate film and laminate foil. This tester uses a hypodermic needle to measure the force needed to penetrate the material, so we can understand how well a material can withstand puncture forces without compromising its integrity.

Anti-puncture Test Standards

ASTM F1306 is a specification regarding the slow rate penetration resistance properties of flexible barrier films and laminates. We follow ASTM F 1306 to perform the anti-puncture test in our laboratory.

Anti-puncture Test Values

The values on the anti-puncture ability of aluminum foil laminate PET12/AL7/LDPE45 is stipulated in the table below.

| Foil Laminate (PET12/Al7/LDPE45μm) | Anti-Puncture ability ASTM F1306 (N) |

| #1 | 7.37 |

| #2 | 7.17 |

| #3 | 7.9 |

| #4 | 7.43 |

Anti-puncutre Test Videos

You are advised to have a further understanding on the test process by watch the video below.

Conclusion

The anti-puncture ability of PET12/Al7/LDPE45μm should not be so great enough to hold products with sharp edge or point, like cooked duck head, however it can meet the requirement of coffee beans and some snacks.

Enhancing the anti-puncture ability can be achieved by modifying the inner LDPE film layer. Additionally, applying another layer of BOPA film can significantly improve the anti-puncture properties, which should be seriously evaluated against the customers’ products.