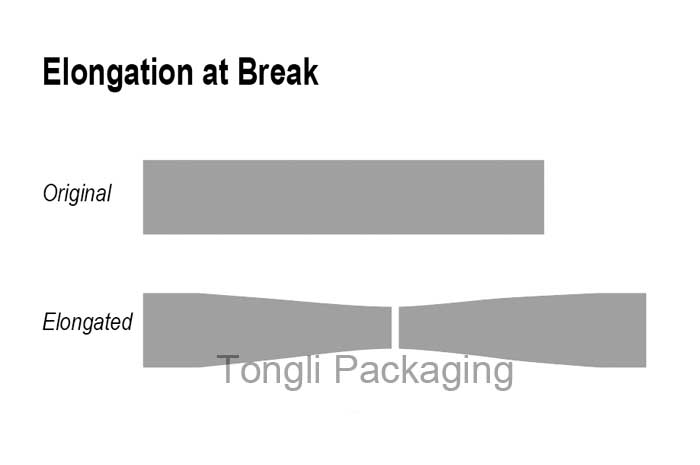

Elongation at break, often referred to as fracture strain or ultimate elongation, represents a crucial material property that gauges just how far a material can stretch before it finally succumbs to failure. Typically expressed as a percentage, this measurement highlights the material’s capacity to undergo plastic deformation, showcasing its resilience and adaptability under stress. A higher elongation at break indicates a greater ability to endure significant stretching without snapping, reflecting the material’s toughness and flexibility in the face of strain.

When a package falls off a shelf and hits the ground, materials with a higher elongation rate can effectively reduce the stress experienced during deformation. In contrast, a film material with very limited elongation, such as aluminum foil, may endure excessive stress at that moment and develop cracks.

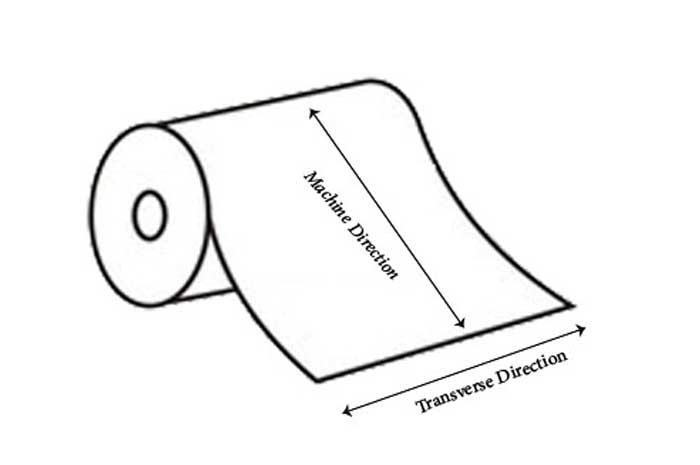

Machine Direction (MD) and Transverse Direction (TD)

When it comes to elongation rate, machine direction and transverse direction should be both evaluated. The machine direction (MD) of a film roll refers to the direction in which the film is manufactured or processed during production. It is normally done by means of a machine direction orienter (MDO) via rolls with increasing speeds The oreintation of the polymer chain will affect the tensile strength, elongation rate and flexibility of the film roll. While the machine direction runs along the length of the roll, the transverse direction spans the width of the film. Typically, films may exhibit different tensile strength, elasticity, and other mechanical properties in the transverse direction compared to the machine direction.

Sample Roll Foil

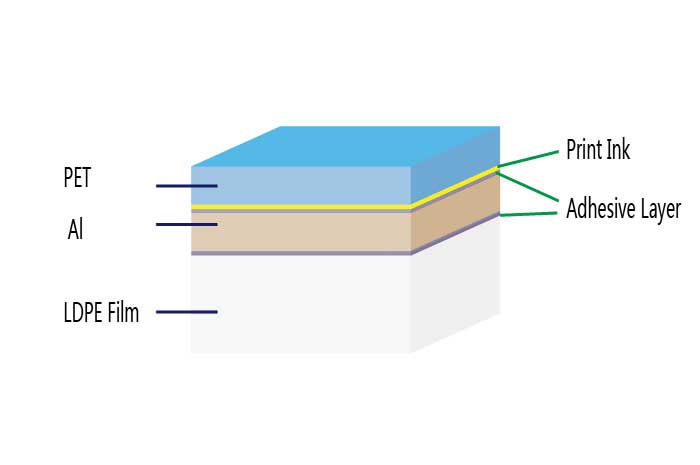

Here, we get triplex-layer aluminum foil laminate well prepared. The foil structure is PET 12um/AL 7um/LDPE 45um, with an overall thickness of 65 microns.

- PET 12 µm, means polyethylene terephthalate membrane stretched in machine direction and transverse direction with thickness 12 microns (equals to 0.48 gauge). It is of great printability, mechanical stability to work as the print substrate in the flexible packaging industry.

- Al 7 µm, stands for food-grade aluminum foil sheet with thickness 7 microns, which is the most cost-effective foil applied in the flexible packaging industry. It is non-toxic, corrosion resistant, light-weight, durable and high barrier.

- LDPE 45 µm, stands for low-density polyethylene film produced by blown process with thickness 40 mirons. It can be modified to meet the stringent requirements of various products.

These 3 layers are combined together through dry lamination and solvent-free lamination craftsmanship in our manufacturing plant.

Test Equipment

Our laboratory is equipped with a GBH-1T tensile strength tester provided by GBPI. This advanced equipment allows us to accurately measure and analyze the tensile strength of various substrate films that we source, as well as any foil laminates produced in our facility.

Test Standards

The elongation rate can be determined using the ASTM D882 standard, which outlines the testing procedure for determining the tensile properties of thin plastic sheeting. This test measures the elongation of a material under stress until it breaks, providing valuable data on its ductility and flexibility. The elongation rate is expressed as the percentage increase in length compared to the original length before testing.

Elongation Rate at Break Values

The values of the elongation rate at break of PET12/Al7/LDPE45 foil laminate are listed in the table below.

| Foil | Elongation Rate at Break (MD) % | Elongation Rate at Break (TD) % |

| PET12/AL7/LDPE45 | 25~35 | 30~40 |

Elongation Rate at Break Test Videos

Machine Direction

Transverse Direction

Conclusion

The 3-layer aluminum foil laminate made of PET/AL/LDPE offers enhanced elongation and flexibility, providing a more durable packaging solution for a variety of products, including tomato ketchup, milk powder, coffee, snacks, pet food, and dog treats. The elongation rate test allows us to accurately assess the properties of the film materials, enabling us to select the best materials and craftsmanship to meet our customers’ requirements.