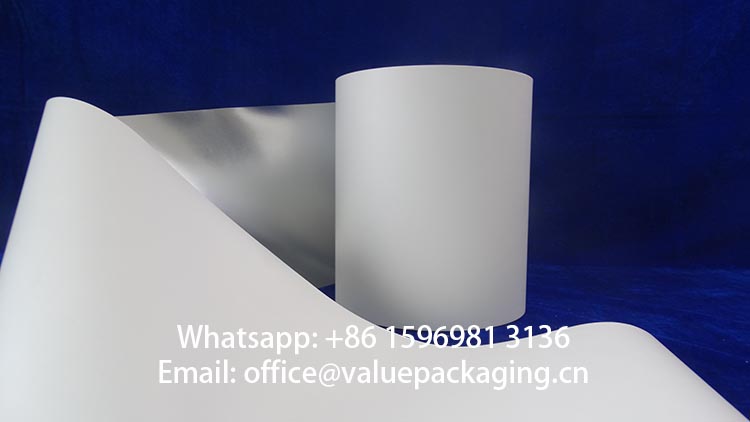

In the aim of meeting the requirements for eco-friendly packages, we have developed compostable and biodegradable film materials into the supply chain, and now we are able to convert below compostable film material into types of foil structures, and meet the specific requirements of the customers.

All these materials are certificated compostable, either industrial compost or home and garden compost. Visit here for the compostable certificates. http://www.valuepackaging.cn/biodegradable-compostable-film-materials/

Foil Structures

Here we are going to list some common foil structures we are now producing, so you can get more on these and choose your ideal package.

BOPLA/PLA Foil Laminate

With good wetting sention, excellent clarity, great mechanical strength, BOPLA film should be a good substrate film for printing process, this foil structure is BOPLA40/PLA40, with total thickness 80 microns. It can be further converted into flat pouch, bottom gusseted standup pouch, Quad seal standing pouch, and box bottom standing coffee bag.

Kraft paper/PLA Foil Laminate

Kraft paper, either brown or white, is widely used in paper packages for coffee beans, dry nuts, foods, snacks etc, with great standing effect for final package. When kraft paper is laminated with inner PLA film, the final foil laminate can be fully compostable. PLA film works as inner sealing layer, and then this foil can be converted into kinds of packages and lidding foils.

Metallized Paper/PLA Foil Laminate

Metallized paper, with a thin layer of aluminum atoms deposited onto the surface of paper (actually many varaiants in applicatioins), is enabled with bright metalic effect and at the same time of high barrier property compared to common paper substrate. This foil laminate should be an ideal packaging film materials for coffee beans, dry nuts, pet treats, snacks etc.

Kraft Paper/BOPLA Foil Laminate

BOPLA film is actually with good sealing property, and it can work as inner sealing layer and formed into kinds of pouches. The weight of Kraft paper applied in this lamiante purpose is usually 40, 50gsm, 70gsm, 80 gsm or even 90 gsm. However, the heavier for the kraft paper, the thicker and more tough it is, and may not be so good to be converted into pouches, as BOPLA film is also very tough, and cause much noisy.

Metallized Paper/BOPLA Foil Laminate

Metallized paper/BOPLA laminate achieves high barrier performance with more tough and rigid effect than Metallized paper/PLA laminate, so when this foil laminate is converted into standup pouches, the standing effect is usually very good.

Metallized Paper/PT Foil Laminate

Cellulose film/Kraft Paper/PLA

This foil structure is very good foil materials when you would like to print your artwork in vivid effect. As the print effect on paper is always a little worse and coarser than that of printed on film. Cellulose film can be considered as clear substrate film with good tensile strength, plus the good wetting tension, all these factors makes cellulos film a good print substrate.

Kraft paper is going to work as middle bone and support layer, and when the foil laminate is converted into standing pouch, it ensures the standing effect for final packages.

PLA film works as the inner sealing layer.

Celloluse film/PLA

this Celloluse film/PLA foil laminated can also be converted into standup pouch even though the standing effect will be a little worse with the middle kraft paper layer removed. However, this foil laminate is semi-opaque, that means the consumers are able to peer into the packages.

Celloluse film/Metallized Paper/PLA

This foil structure is achieved with a aluminum metallized layer which is able to provide higher barrier performance, and on the other hand, it will make the artwork print more vivid and solid, as the sunlight is reflected by this metallic layer.

BOPLA/Metallized Paper/PLA

This foil structure can be achieved in our produce, however not well advised for the customer application, as of below reasons.

Potentital heat damage on BOPLA surface

To convert this foil laminate into packages, certain temperature and pressure should be applied on top of BOPLA film. However, metallized paper is not good heat transfer material, that means to make the PLA film well sealed, higher temperature and pressure may be applied on the outside layer of BOPLA film, that may cause damage to the appearance.

Cost consideration

At present, the cost for BOPLA film is much higher than cellulose film in china market, as the BOPLA film market is just at start up, and there are only limited manufacturers that are able to mass produce this film, so the price is somewhat higher than it should be. Hope the market for BOPLA film becomes mature soon, so the price should go lower to normal level.