[metaslider id=”5828″]

BOPLA film is short for biaxially-orientated polylactic acide, which is usually derived from bio-chemical materials like corn tarch, potato tarch, which can be fully biodegradable or compostable in nature conditions. After biaxially orientation, below properties are being improved.

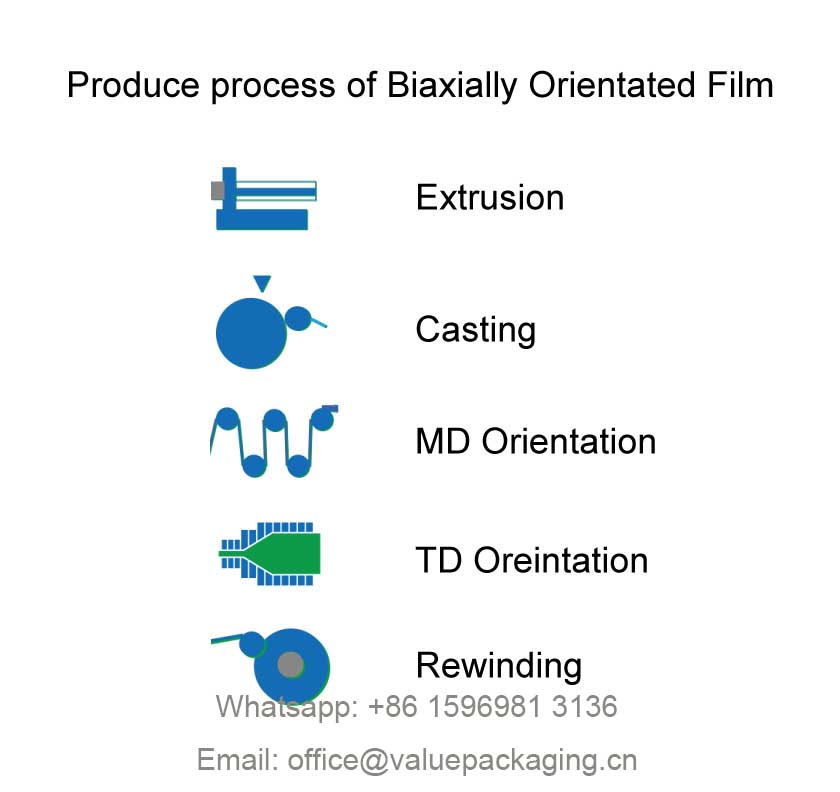

For any produce of biaxially orientated film, it should go through the craftsmanship of extrusion, casting, MD orientation, TD orientation (sometimes MD and TD orientation are realized simultaneously), and finally rewinding, with graphic as below.

After MD and TD orientation, the molecular in the casted melt films are parallelized, which will improve some properties of the final film, like mechanical strength, clarity, printability, etc.

BOPLA film should be considered as polar film material, with excellent dyne level on both inner and outer side. With good clarity, BOPLA film can be printed directly on the surface or reversely on the inner side.

Below package for flower and bread are directly printed on the outside surface of BOPLA film.

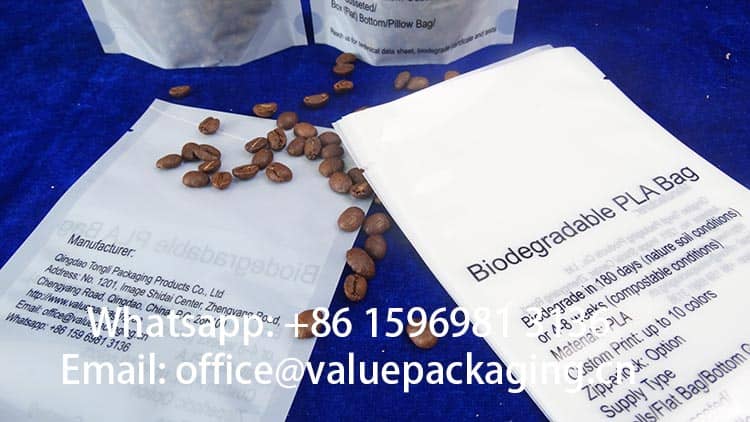

Below pouch is to print artwork on the inner side of BOPLA film and then laminate with PLA heat seal film, and converted into final pouch.

You are advised to read more here to understand the print process.

BOPLA film can be laminated with other film material to achieve multi-function pupose, below list are some foil structures in our produce

Read here for more understanding on the foil laminate based on BOPLA film.

BOPLA film and its laminate can be further converted into kinds of packages, as below

This BOPLA film is certificated by TUV for industrial compostable product, and you may read the certificate as attached.

You can also learn about our compostable test of BOPLA film in nature soil conditions.

Here attached the typical technical data sheet for this BOPLA film, for your reference.

We are trying to revert the test process for BOPLA film, so the customers will be able to have an actual understanding.

BOPLA film is intended to degrade or compost in nature conditions or compostable conditions. Please read more on our test process for BOPLA film in nature soild conditions.

Tensile strength is an important index to check the mechanican performance of a film material, and you may get a further understanding by the tensile strength test with the picture below.

The sealing strength for BOPLA film 40 microns should be expected to perform at 12~14N/15mm, and you watch the video test process by clicking the below picture.

BOPLA film proves to be one of the superior packaging film in flexible packaging industry, and now have been used in packages for flower, gift, foods like bread and biscuit, coffee beans. Actually, the biggest factor that inhibit the application of this film is the cost, as it is just at the startup period for this film and the price is somewhat higher. Hope the price will be lower and lower so it can extend its superior advantages to other fields.