VMPET film is short for vacuum

Main Properties

High Barrier Performance

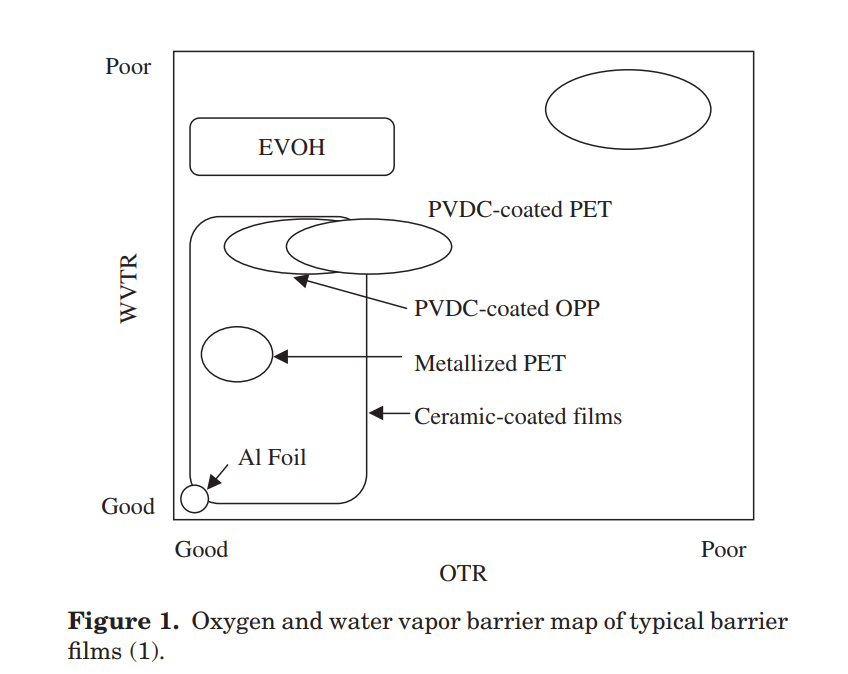

The reason why VMPET film is so widely used in standup pouch packages is the high barrier property at quite lower costs than aluminum foil.

As you can understand from above table, the barrier performance for VMPET film is only a little worse than Aluminum foil and ceramic coated films, however the price of VMPET film is only 1/3~1/2 of aluminum foil and 1/10~1/8 of ceramic film.

Bright Metallic Effect

When it comes to standup pouch packages, bright metallic effect means the final package can be realized in a more vivid and solid effect. As when the ink is printed on a clear transparent PET film, actually, the actual artwork can be halfly seen through even laminated with another PE layer. You can compare the two standup pouch package below.

Sunlight Shield Property

Sunlight shield property means the package with VMPET film can well protect the inside products against sunlight, like potato chips, liquid detergent, cookies, instant noddles etc. VMPET film is the best solution for these products packaging.

These 3 excellent properties lead VMPET film to be widely used in flexible packaging and standup pouch packages.

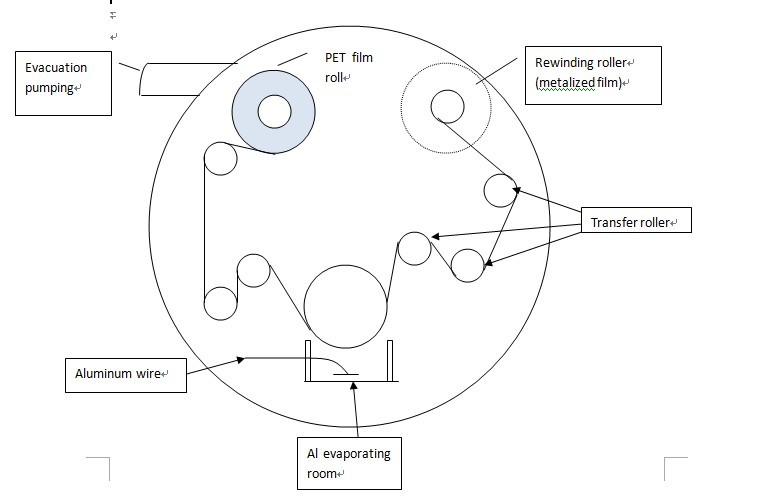

So, how VMPET film is produced?

Vacuum metallization for aluminum wire can only happen under vacuum conditions, as if there is any air inside the metallizing machine, the oxygen will lead aluminum wire to burn easily, and may also lead to explosion, as during production, the temperature will have to be heated up to nearly 2,000 celsius degree to evaporate the aluminum wire into aluminum gas, so the aluminum gas can deposit uniformly onto the surface of PET film.

The thickness of aluminum layer is very thin, only 350-450 ? (1 ?=10^