Burst Strength Test on PET/AL/LDPE Multilayer Laminate

A burst strength test measures a material’s ability to withstand internal pressure before it ruptures.&nb...

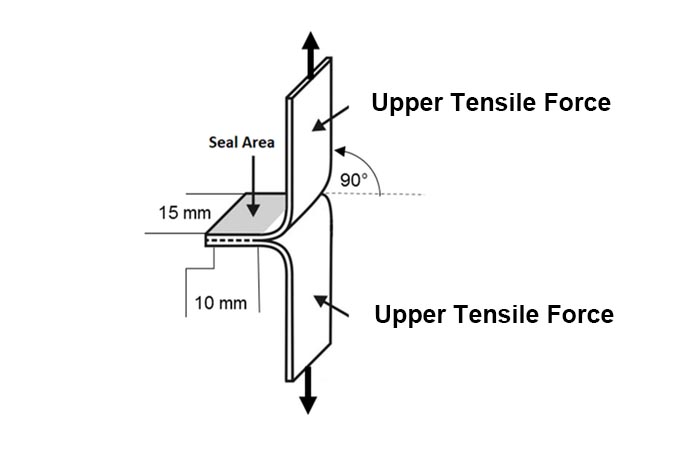

Sealing Strength Test on PET/AL/LDPE Multilayer Laminate

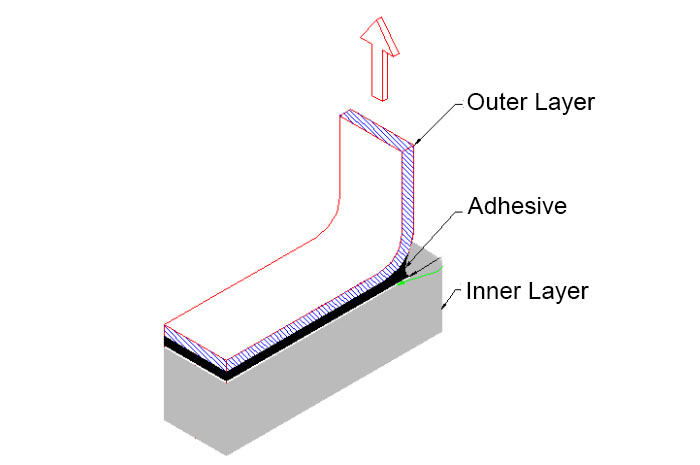

Seal-welded-on-box-bottom-pouch

For any flexible pouch package, it is necessary to weld and seal one piece of foil...

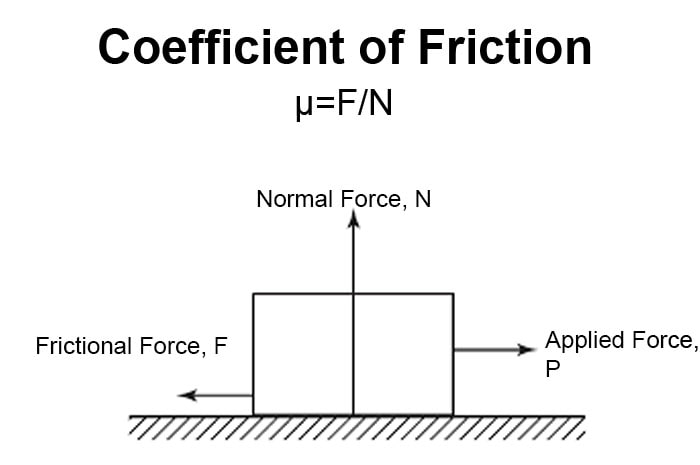

Coefficient of Friction Test on PET/AL/LDPE Multilayer Laminate

The coefficient of friction in flexible packaging greatly affects how easily one surface slides over another. This f...

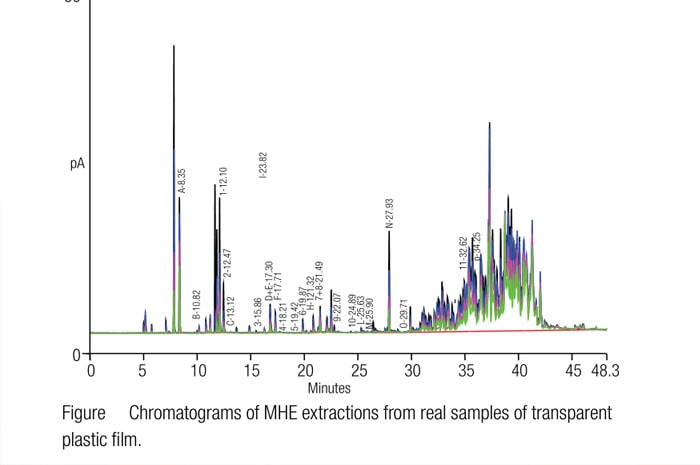

Solvents Leftover Test on PET/AL/LDPE Multilayer Laminate

VOCs, or Volatile Organic Compounds, are a group of carbon-based chemicals that readily evaporate at room temperatur...

Peel Strength Test on PET/AL/LDPE Multilayer Laminate

In flexible packaging industry, several film materials will have to be combined together to function in a whole pack...

Elongation Rate Test on PET/AL/LDPE Multilayer Laminate

Elongation-at-break

Elongation at break, often referred to as fracture strain or ultimate elongation, represents a...

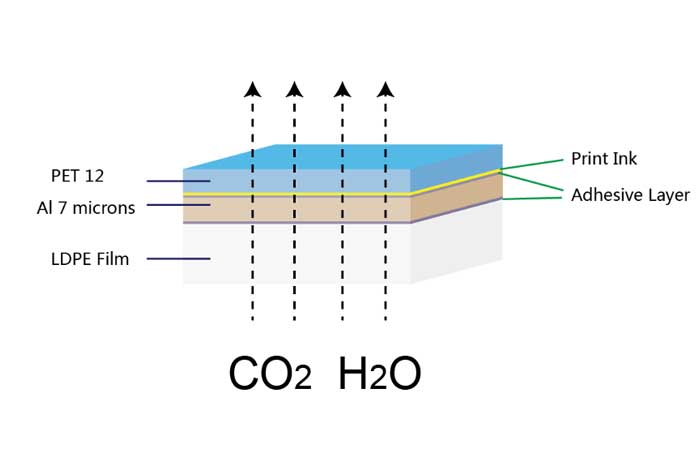

MVTR and OTR barrier properties of PET/AL/LDPE Multilayer Laminate

Flexible packaging materials must protect products from various environmental factors, including oxygen, nitrogen, c...

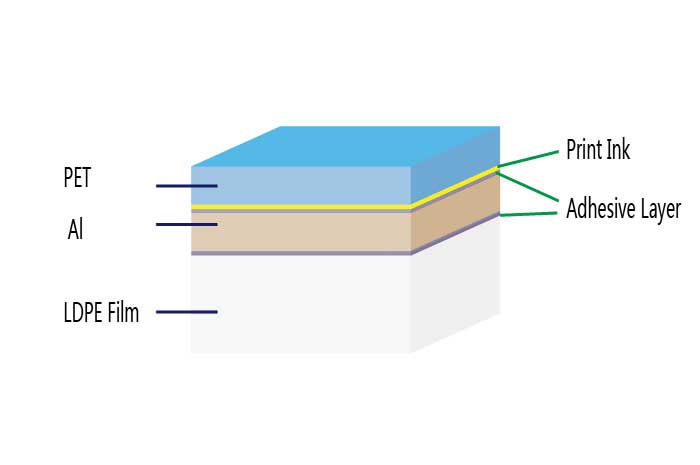

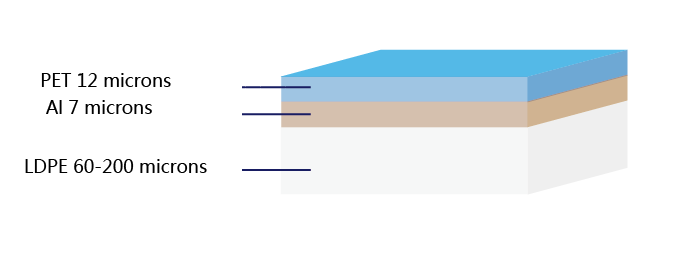

What’s PET/AL/LDPE triplex foil material

When it comes to flexible packaging, aluminum foil sheet is considered as the best ideal package material with the b...