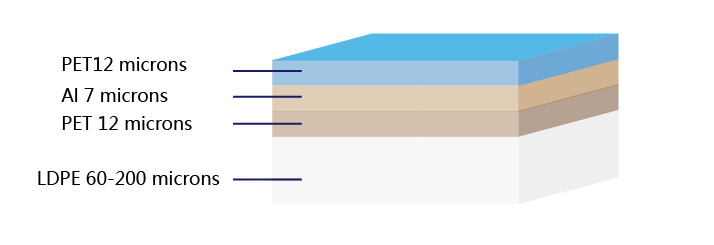

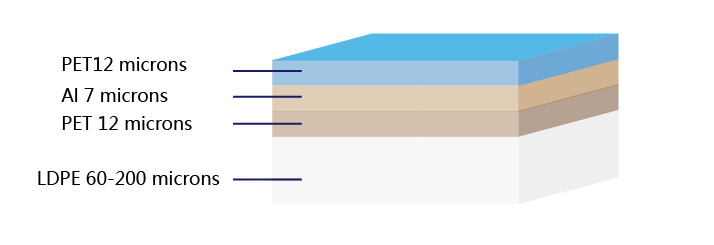

PET/AL/PET/LDPE foil laminate is intended to describe a 4-layer laminated foil that combines 4 substrate films in an outer-to-inner sequence with graphic shown as below.

Al is short for aluminum foil, that is a thin layer of aluminum metal used in flexible packaging, that can be considered with the best barrier performance of all the substrate materials.

so, with this aluminum foil included in this laminate, this 4-layer foil laminate can be considered one of the top barrier packages for the products that require great protection against outside factors, like oxygen, sunlight, water vapor, etc, among which food, juice and coffee beans are the most popular applications.

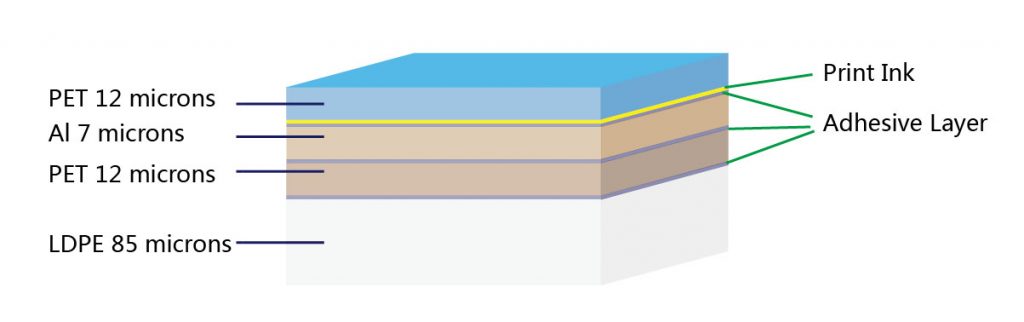

When the artwork is reversely printed on the inner side of outside PET film, the ink is physically trapped between the first PET film and aluminum foil layer. Further more, when the adhesive layer is stipulated, the exact graphic for this foil should be as below.

Usually, there are 3 well-operated craftsmanships to coat the thin adhesive between the two layers,

| Craftsmanship | Advantage | Shortage |

| Dry Lamination | suitable for combining many substrates in small batches | some extent of solvent may be left in the final laminate foil |

| Solvent-free lamiantion | No need to use solvent in adhesive coating | can only be intended to bond non high barrier films |

| Extrusion Laminaton | only resins used, no need to use polyurethane adhesive, that is much better for human foods safety. | only cost-effective when the order is large |

In our manufacturing plant, we apply dry lamination and solvent-free lamination process.

Ok, here we come to the key question, why there is extra PET film than the most common PET/AL/LDPE foil laminate?

As explained, aluminum foil is thin metal sheet, without any elongation rate. However, LDPE film is short for low density polyethylene film with very high elongation rate, sometime will reach 1500-1600% of its original.

Check below video for the test of elongation rate for LDPE Film

The serious unbalance in elongation rate cause poential delamination problems between aluminum foil and LDPE film when unexpected shock strength is implied upon the foil laminate, like the package drops unexpected from the goods shelf. In some cases, when the foil laminate is crumpled, there may be some tiny broken holes on the aluminum foil, that will lower the barrier performance.

So a certain buffer layer is essential, among which PET and PA film are the most used. As the price for PET film is only 1/2~1/3 of the PA film price, so in normal cases, we would advise to use PET film as buffer layer. However, if the customer is just looking for the premium quality package, just use PA film as buffer layer, PET/AL/PA/LDPE is approved to be the best of all the aluminum foil laminates.

Further more, with another buffer PET film layer, this PET/AL/PET/LDPE foil laminate can be more stable and reliable for afterward process, just as welding a degassing valve or plastic spout onto the foil pouch.

We will share more knowledage about the welding of degassing valve and spout in future posts.

Hi,

My name is Paul Homnick and I’m a principal scientist at Bausch and Lomb.

I’m interested in your PET-Alu-PET-LDPE films. Do you produce this film construction with the aluminum layer being on the order of 40-80 microns thick? If so, I would like to evaluate samples and/or quote. If not, would a film of this construction be feasible for a pilot run?

Thank you for your help.

Paul