PET film is short for Polyethylene terephthalate or polyester film, that is a versatile plastic film that can be well used for many applications, such as flexible packaging, optical area, electronic insulation, heat transfer film, marking film and graphic arts.

Of course, when it is intended to each specific application, the property will have to be seriously optimized to meet the final application requirements, and in this article, we are going to talk about the refined property for PET film when it is used in flexible packaging industry, hope the customers will get a basic understanding on its property, and make the best choice for their packages.

Thickness

The most common used thickness of PET film in flexible packaging is 12 microns, that is equal to 48 gauge or 0.47 mil, as this thickness has been verified as the best balance among different property and cost consideration.

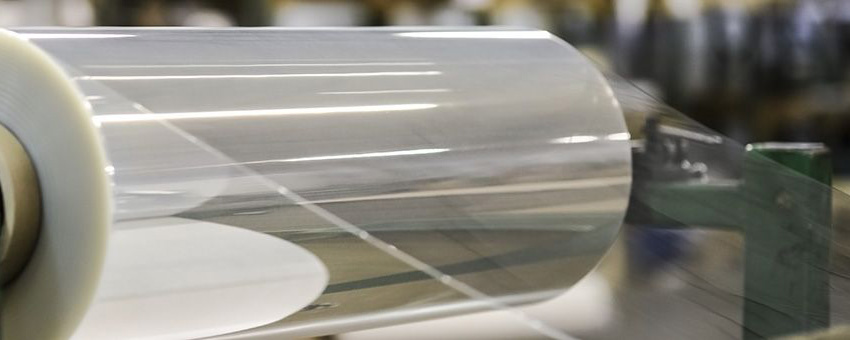

High Transparency

High transparency for the PET film body is absolutely imperative when the artwork design is printed onto the surface, and the PET film body will not affect the color presentation from the original artwork

As you can find out from the photo, any tiny contamination point can be seen through the high clarity for PET film.

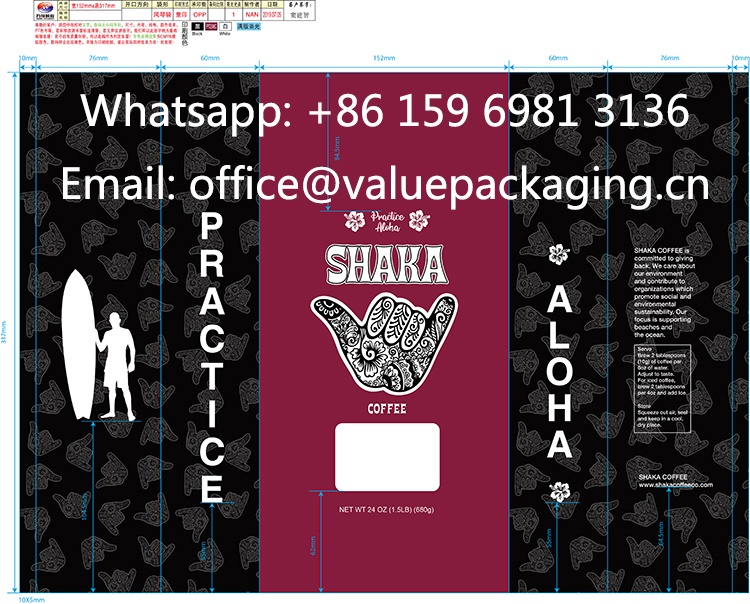

Great Printability

Great printability allows the ink to have a fine leveling during print process, and after drying, the ink will adhere tightly onto the surface of PET film.

PET film is polar material, which is born with good wetting tension on the surface, that is helpful for the adhesion of inks. In actual application, usually the PET film will have to be corona treated to strengthen the dyne level for the surface, and make it more durable in storage.

However in some hot and wet areas like South America, the over-dose moisture in the atmosphere and high temperature will highly accelerate the weakening of wetting tension that is so bad for print, and may cause quality accident in print produce, so the PET film will have to be chemically coated to fight against quick weakening, and we will give a futher analysis on this in further posts.

Great Dimensional Stability

PET film, should be biaxially oriented in produce to strength the dimension stability. When the PET film roll is uploaded to the release roller on the print machine, the film will be applied a certain tension in the machine direction to make it as flat and smooth as possible to accept the fine leveling of the inks and coatings.

Great dimensional stability allows the manufacturer to achieve lower cost by improving the machine running speed of all the phases of conversion.

Take printing for example, previously the running speed is 100-120 meter per minute, and now more printing machines are running at 180-250 meter per minute, and some machine are even working at 300 meter per minute, that will allow the manufacturer to use less labor, less time to produce certain order.

Good Stiffness

Good stiffness is great help when we want to achieve good standup effect for the final package, especially the standup pouch packages for liquid products, such as liquid laundry detergent or windshield washer fluids in 1-3liters.

For liquid products, they are versatile and flexible, if the standup pouch is not able to provide good stiffness, the liquid produce may collapse in the package, that is so bad for product branding and sale.

and PET film comes to the right provide for good stiffness. Upon our experience, all of the 1-3 liter standup pouch produced for liquid product should contain PET base film, and the packages with PET film is always more stiff than the package with PA film.

Read this article for detailed understanding on 5liter standup spout doypack with different stiffness

Temperature resistance

PET film intended for flexible packaging purpose is modified to work well in temperature from -70