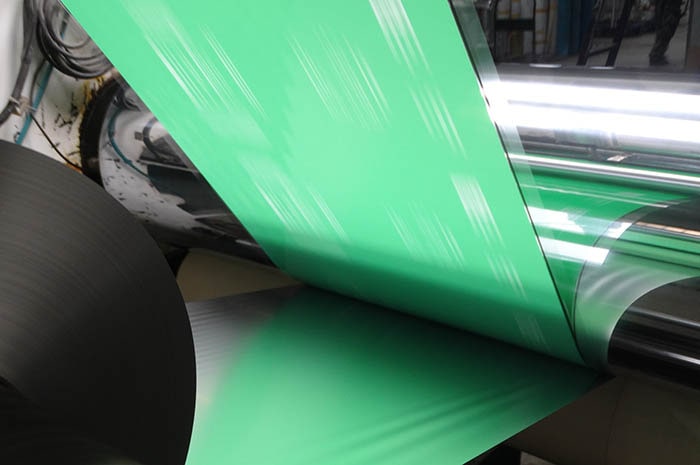

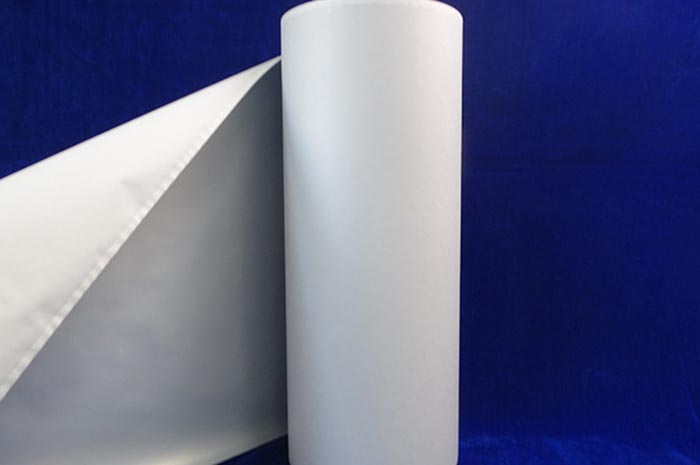

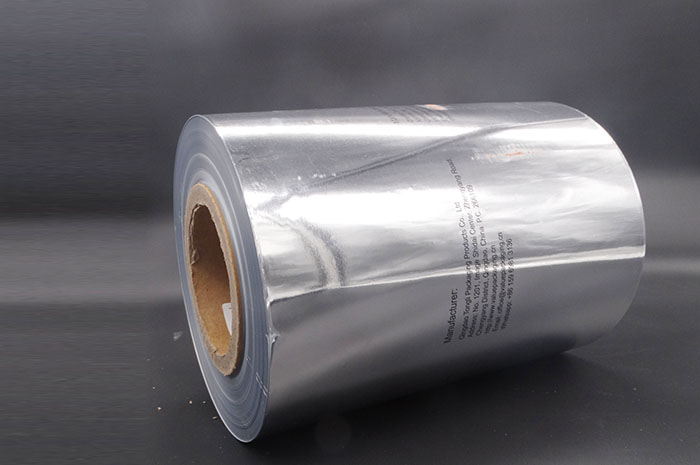

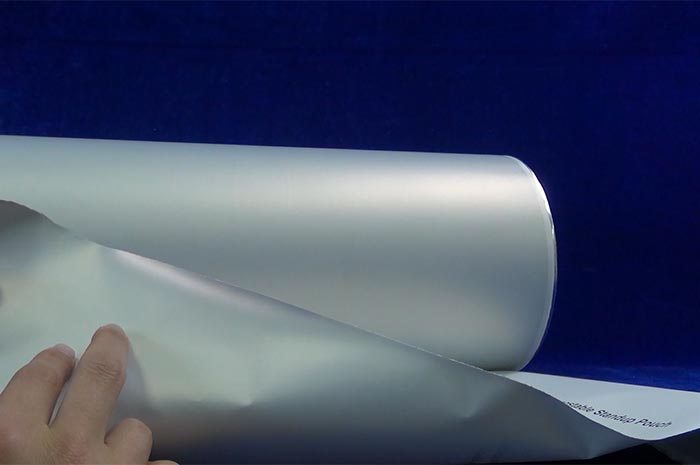

Gorgeous compostable pouches are achieved based on metallized cellulose

Our company is now outputing gorgerous compostable pouches and rolls for various products based on metallized cellulose paper. When metallized cellulose film is trapped between the foil materials, Not only the print effect is largely imporved win vivid effect, but also the protective function is reinforced as final packages.