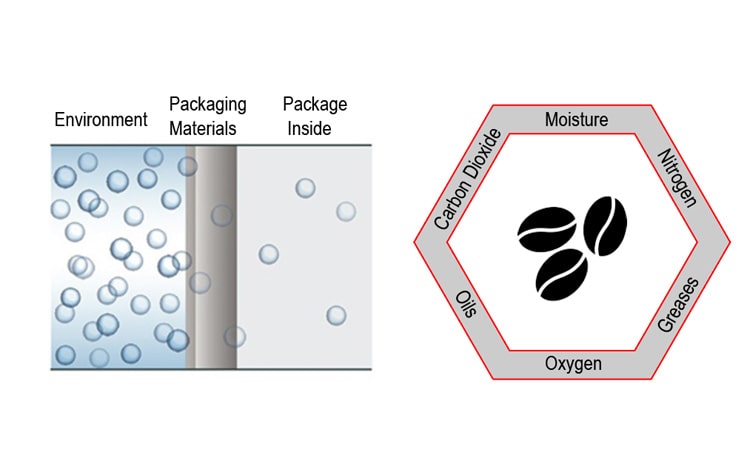

Flexible packaging materials must protect products from various environmental factors, including oxygen, nitrogen, carbon dioxide, moisture, greases, and oils. Among these, oxygen and moisture can cause the most significant harm to food products. Oxygen can significantly harm food by causing various types of spoilage, including oxidation, microbial growth, and changes in color, flavor, and texture. Moisture, or high humidity, can negatively impact food in several ways, primarily by promoting microbial growth and accelerating deterioration. Therefore, it is essential to test and evaluate the permeation rates of oxygen and moisture through specific packaging materials before finalizing the packages for our customers’ products.

In this post, we will explore the test of oxygen transmission rate and moisture vaport transmission rate agaisnt triplex aluminum foil laminate PET/Al/LDPE.

MVTR

MVTR, stands for moisture vapor tranmission rate. It is the index to describe the amount of moisture vapor that can pass through a specific packaging materials under certain conditions (temperature and relative humidity) over a period of time. It is typically expressed in grams of water vapor per unit area per unit time, such as g/m²/day or g/100 in²/24 hrs.

OTR

OTR, stands for oxygen transmission rate. It is the steady state rate at which oxygen gas permeates through a specific packaging material at specified conditions of temperature and relative humidity. The values are usually expressed in cc/100 in2/24 hr in US standard units and cc/m2/24 hr in metric (or SI) units.

Sample Foil For Tests

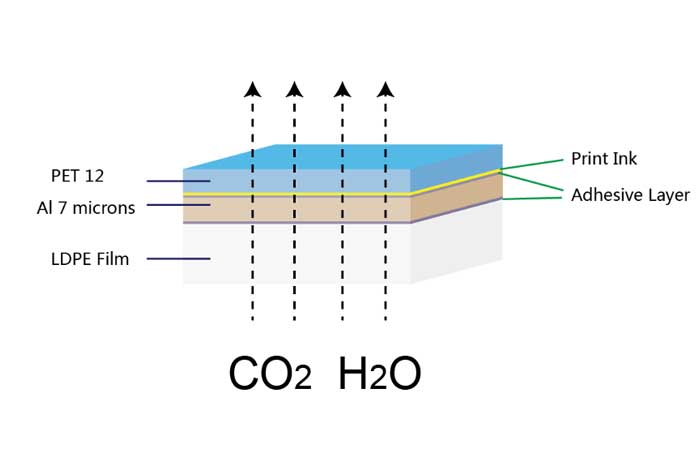

Here, we get triplex-layer aluminum foil laminate well prepared. The foil structure is PET 12um/AL 7um/LDPE 60um, with an overall thickness of 80 microns.

- PET 12 µm, means polyethylene terephthalate membrane stretched in machine direction and transverse direction with thickness 12 microns (equals to 0.48 gauge). It is of great printability, mechanical stability to work as the print substrate in the flexible packaging industry.

- Al 7 µm, stands for food-grade aluminum foil sheet with thickness 7 microns, which is the most cost-effective foil applied in the flexible packaging industry. It is non-toxic, corrosion resistant, light-weight, durable and high barrier.

- LDPE 40 µm, stands for low-density polyethylene film produced by blown process with thickness 40 mirons. It can be modified to meet the stringent requirements of various products.

These 3 layers are combined together through dry lamination and solvent-free lamination craftsmanship in our manufacturing plant.

Test Equipment

Under our laboratory conditions, we carry Mocon AQUATRAN 3 Analyzer to perform the MVTR test, and Mocon OX-TRAN 2/22 Series to perform this OTR test.

OTR Test Standards and Conditions

The standard test for measuring oxygen transmission rate is ASTM D3985 for dry conditions and ASTM F1927 for moist conditions.

OTR testing is typically performed at precise temperature and relative humidity levels to accurately mimic the environmental conditions that the material will encounter during its practical application. While a common standard for this testing is 73°F (approximately 23°C) with a relative humidity of 0%, it is important to note that different conditions may be selected based on the specific requirements of the material’s intended use. For example, in scenarios where the packaging will be exposed to higher humidity or temperature fluctuations, adjustments to these parameters are made to ensure that the testing reflects real-world usage. This careful calibration serves to provide a reliable assessment of the material’s performance characteristics under varying conditions.

MVTR Test Standards and Conditions

The standard test for measuring moisture vapor transmission rate is notably defined by ASTM E96 and ASTM F1249. ASTM E96 describes two methods for measuring MVTR: the Desiccant Method and the Water Method. Both methods utilize a test dish and controlled conditions. ASTM F1249 measures the water vapor transmission rate through flexible barrier materials using a modulated infrared sensor, making it especially useful for packaging films.

The conditions under which MVTR tests are conducted are essential for obtaining accurate and reliable results, as both temperature and humidity can greatly affect the outcomes. Typically, these tests are performed at a temperature of 100°F (37.8°C) with a relative humidity level set at 90%, creating an environment that simulates extreme conditions for various materials. This standard testing setup helps in assessing how effectively a material can allow moisture vapor to pass through it. However, it is important to note that depending on the intended application and specific properties of the materials being evaluated, other combinations of temperature and humidity may be utilized. For instance, certain applications may require testing at lower temperatures or varying humidity levels to better reflect real-world conditions. Adjusting these variables allows for a more tailored analysis of a material’s performance in specific environments.

Test Values

The test values of MVTR and OTR of PET12/AL7/LDPE60 are stipulated in the table below, which are quite helpful to decide on the materials for a product.

| Item | WVTR @38℃, 90% RH (g/m2/24hr) |

OTR @23℃, 0% RH (cc/m2/24hr) |

| PET12/AL7/LDPE60 | 0.01 | 0.01 |

Conclusion

The triplex aluminum foil laminate PET/AL/LDPE is of excellent barrier properties to meet the stringent requirements of various products such as tomato ketchup, milk powder, flavored juice, coffee, nutritions, supplements, baby foods, yogurt, tablets, condiments, dried nusts, snacks, fruit jam, tea, pet foods, sunscreen etc. It is able to protect them from the worst environment, and keep the freshness and flavors of the foods products in an extended period. The thickness of each layer will be carefully evaluated and decided, to get a good cost-effecitive materials for the applications.

In some cases, the triplex foil materials may have to be reinforced with extra layer like PET film, BOPA film, to present more robust properties for some products. You may contact us for further assistance whenever you have any problems.